AEROMAN

Develop a robust AM method for aerospace components to replace traditional production methods

Context:

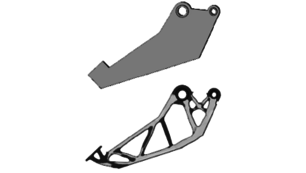

AEROMAN project intends to develop a robust additive manufacturing process for aerospace components, that are currently being manufactured through traditional production methods. The project involves qualitative benchmarking of the two mostly used technology namely laser beam powder bed fusion (PBF-LB), towards developing a comparative framework for selection of the best AM processes and for specific aerospace applications.

The challenge:

- Feedstock procurement, high material cost and environmental impact.

- Complying with aerospace-related specifications and requirements.

- 30% energy reduction and up to 60% cost and lead reduction.

- Reducing the buy-to-fly ratio in the range of 15:1 to 30:1 closer to 2:1.

Supplier:

User: