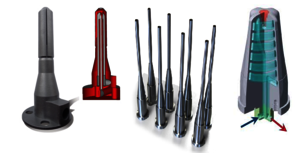

Smooth surfaces conformal cooling inserts

CLIMATE realises conformal cooling inserts with significantly enhanced surface roughness through a lithography based metal printing process. This allows the creation of surfaces with advanced properties. To enable the continuous achievement of such properties, design guidelines are needed to realise the final geometry without post processing.

From challenges so solutions

The challenge on CLIMATE is to achieve robustness for the basic manufacturing technology. This addreses process parameters as well as the definition of design guidelines that ensure production of the final geometry to the specifications. The main objectives in this progress are:

- Reduced structure size that can be achieved reliably and maintained during use of the insert

- Competitive cost for the solution from design to the use of the insert

The application of the new printing technology to the production of mould inserts will demonstrate the viability of a process that achieves its specifications without post processing. The potential reduction of additional steps in the manufacturing process chain for the tool itself addresses not only the cost for the mould but also the time to market for such solutions. Other areas of application where low surface roughness is needed will profit from the success of this experiment.

CLIMATE addresses a reduction on two scales, the production of the tool and the production of parts with the tool. The challenge is to meet the requirements in quality of the tool insert at a suitable cost level to provide benefits in comparison to classic post processing.

Increase productivity: The success of CLIMATE will increase productivity in two dimensions: the production time for a mould insert as post processing becomes redundant. In a second dimension, the production rate of the injection mould parts can be increased through better thermal cycling which is achieved through the increase in structural detail of the cooling channels.

Price: The combination of redundant post processing and increase in production rate will create a cost benefit for CLIMATE inserts.

Environmental: An increased production rate at comparable energy supply will yield a smaller ecological footprint per final product.