MOMO3D

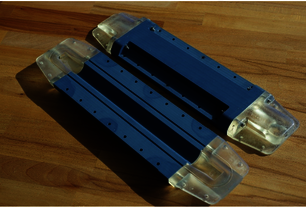

Maximum modularity of moulds - Reinventing mould for maximum modularity of complicated or/and multi-parts one

Context:

When dealing with fibre reinforced polymer structures, a complex and expensive industrial equipment and tooling is needed to shape the final product. Modular moulds that can be used for different geometries, parts or subassembly, are the key innovation. The most affected customers are SME working in the aerospace and space field or/and where the number of products to be manufactured is limited and customized to custom requests. On the market there is a restricted niche of companies providing this off-the-track service exploiting subtracting technologies. Moreover, if it is offered, it has a huge price difference with respect to nominal product in terms of non-recurring cost.

The challenge:

- Develop AM mould inserts that

- Fulfil tight tolerances

-

- Integrate functionalities

- Validate their use in milled moulds

- Assembly and fit check

- Reusability after production loops

- Realise one sample configuration

- To significantly reduce the effort for mould making/adaptation in complex regions

- Up to 75% faster production time

Less material use/waste

Supplier:

https://spacestructures.de/